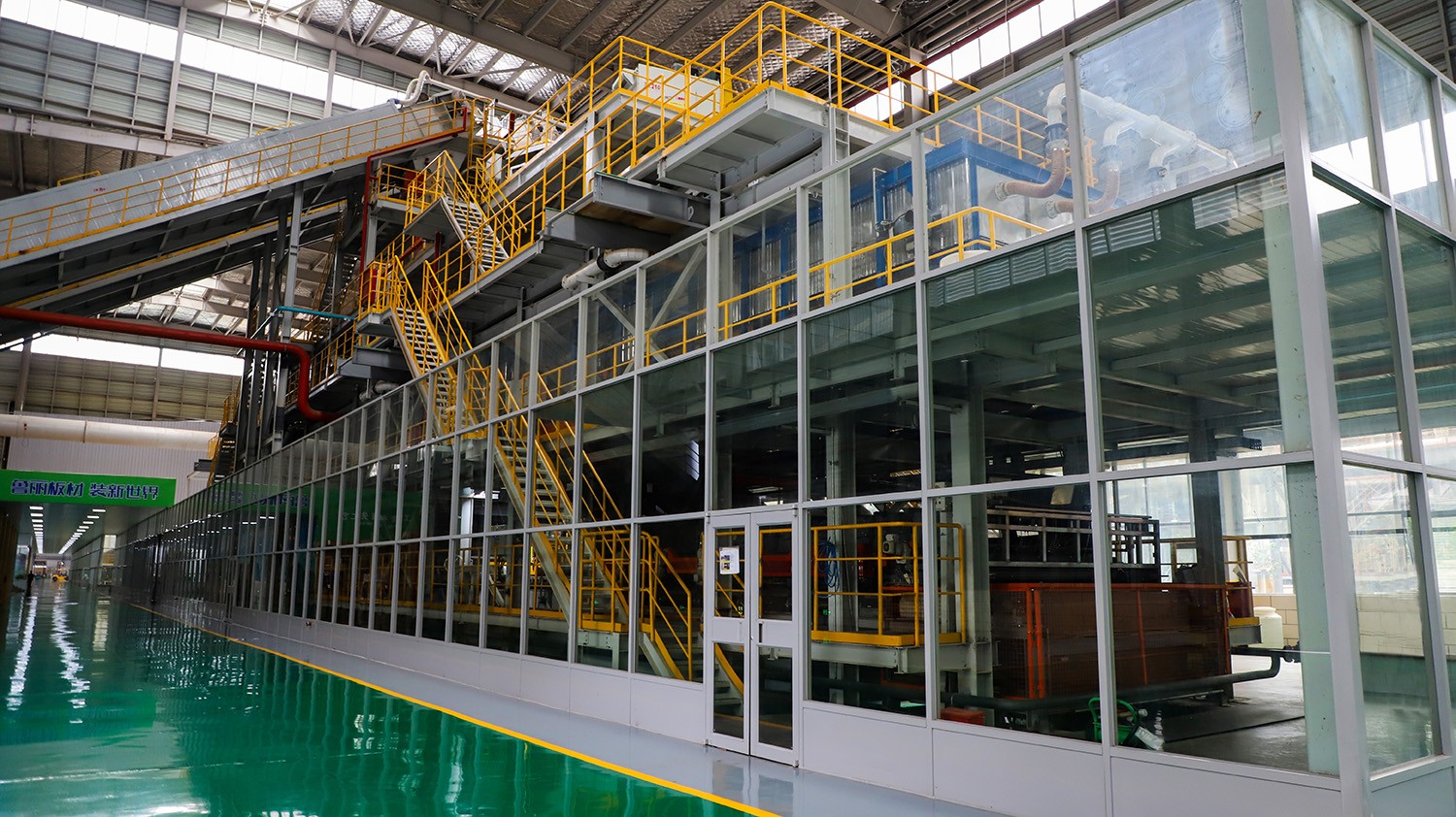

Finished Boards Workshop

The 16# Fine Board Workshop Project invests 450 million yuan, covering 49.3 acres with annual capacity of 452,000 m³ OSB panels and 48,000 m³ ultra-tactile UV boards. Developed jointly by Luli Wood and Germany’s Vencona, it integrates green and smart manufacturing through automated control systems and big data, achieving intelligent, digital, and visual production. Domestic-leading equipment enables one-stop processing (printing, glue-dipping, pressing, UV) with high-precision synchronous pattern alignment, delivering 5x efficiency over traditional presses, lower costs, and superior quality.

1. Vencona’s short-cycle pressing lines minimize thickness variation across materials, featuring automatic surface cleaning, glue-paper handling, and rapid cooling (<40°C) to replace traditional curing cycles.

Vencona’s pattern alignment uses HD imaging to synchronize woodgrain paper and steel template textures, replicating natural wood aesthetics.

2. Ywega’s high-speed glue-dipping line (30-35m/min vs. domestic 20m/min) ensures precise glue application via automated mixing, tension control, and energy-efficient drying.

3. German Lutz-based printing lines operate at 250-300m/min (vs. domestic 120-150m/min) with unmatched registration accuracy. Equipment includes 4 Vencona presses, 4 Ywega dipping lines, 4 rotary printers, and smart warehousing. Vencona lines 1-2 operate normally; line 3 starts production in November; line 4 completes installation in December. Ywega lines 1-2 run; line 3 begins trial. Printer line 1 (5-color) functions; line 2 (4-color) installs mid-month.

Post-completion, annual revenue targets 1.57 billion yuan (profit-tax: 220 million yuan), advancing green development in wood panels and home furnishing.