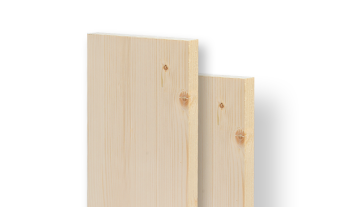

Spruce Finger-Jointed Board

Spruce Straight-Jointed Board

Knot-Free Radiata Pine

Radiata Pine Straight-Jointed Board

Export Radiata Pine

Systematic Analysis

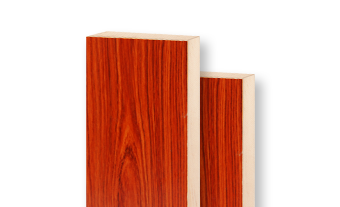

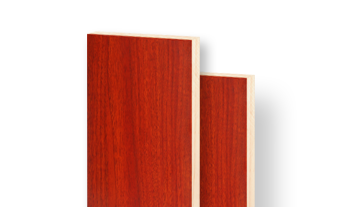

Heavenly Rosewood

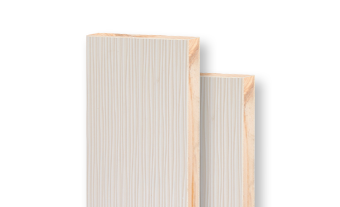

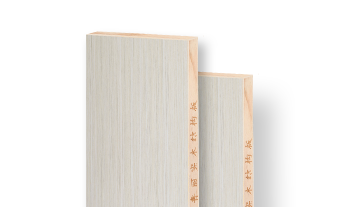

Floating Threads Like Snow

Gentle Tenderness

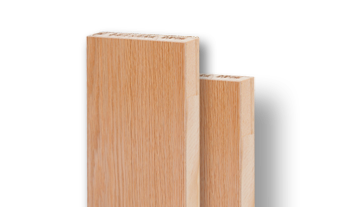

Solid Wood Structural Board Veneered with Red Oak Veneer (UV)

Solid Wood Structural Board Veneered with Red Oak Veneer (without UV)

Solid Wood Structural Board Veneered with Radiata Pine Veneer

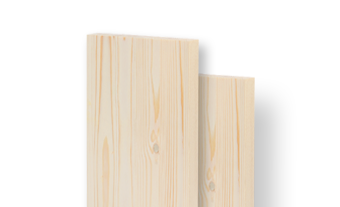

Luli Wood Glulam

Luli Boards, Define New Worlds.

Luli laminated wood features advanced production: selects premium imported timber, processed through automated grading saws, spliced with German technology. Delivers smooth, aesthetically seamless surfaces. Uses eco-friendly adhesives superior to National Standard (E1), ensuring health and environmental safety.

Zero Formaldehyde Added

Imported Logs

German Technology

High Nail Withdrawal Resistance

Water & Moisture Resistant

| Product Name: | Glulam | ||

| Substrate Thickness: | 9mm-40mm | ||

| Material Composition: | Radiata pine | ||

| Product Density: | 400kg/m³ | ||

| Product Grade: | HENF | ||

| Formaldehyde Emission: | Zero Formaldehyde Added | ||

| Specifications: | 1220×2440mm | ||

| Water Content: | 8%~12% | ||

| Product Features: | Zero Formaldehyde Added, Imported Logs, German Technology, Solid Wood Panel, Warp-Resistant | ||

| Main Purpose: | Furniture, Interior Decoration, Building Components, Wood Door Panels, Wardrobes, Doors/Windows, Countertops, Wall Panels, Ceilings, Instrument Soundboards, etc. | ||

Glulam

Eco-Health: Zero Formaldehyde Added production with MDI eco-adhesives. Chemically stable, achieves HENF rating, holds US NAF certification. Safely used for interiors and furniture.

Superior Performance: Premium imported pine excels in directional strength, durability, moisture resistance, dimensional stability vs. standard particleboard. Less cracking/warping than solid wood with better tensile/compressive strength.

Aesthetic Appeal: Precision-processed smooth surfaces with seamless joints, uniform stable color. Showcases natural wood texture/grain with high decorative value.

Processing Efficiency: Superior nail-holding power. Easily cut, drilled, carved, sanded. Meets diverse furniture/decoration needs with enhanced construction efficiency.

HEALTH CARE

Nothing Matters More Than Your Health.

Manufacturing with Zero Formaldehyde Added, Eco-Friendly, Water & Moisture Resistant

For Your Family's Health.

Automated timber grading saws select materials, processed with German splicing machines ensuring smooth aesthetic surfaces;

Uses MDI formaldehyde-free adhesives, with high-temperature pressing enhancing stability for select products.

Zero Formaldehyde Emission: Eco-adhesives combined with formaldehyde-free technology meet healthy home demands;

Warp/Crack Resistance: Cross-layered core structure (e.g., 3-ply composite) enhances board strength;

Versatile Applications: Custom veneers (e.g., red oak, ash) available per client needs.