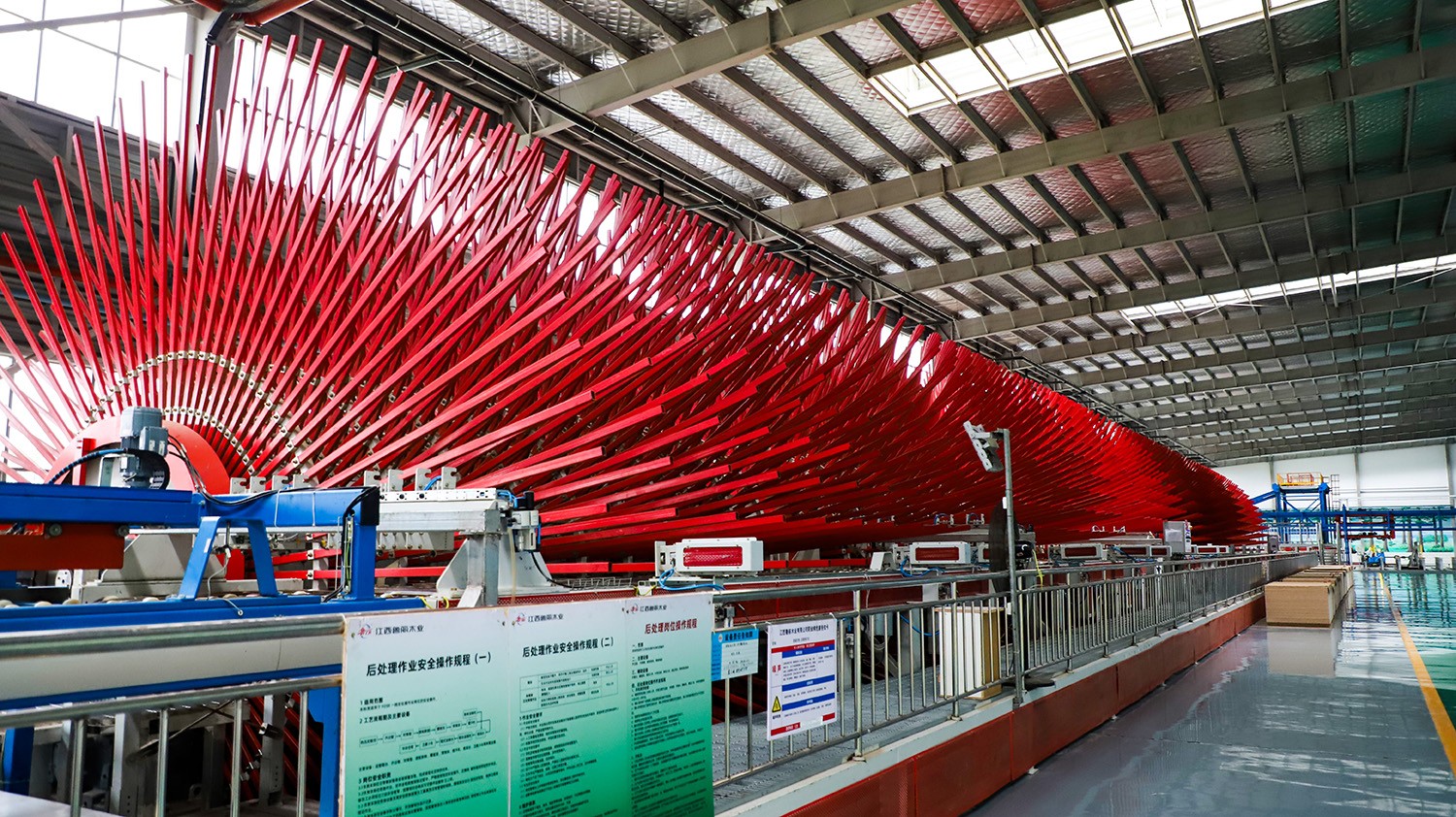

Dieffenbach Continuous Press

Founded in 1873 and headquartered in Eppingen, Germany, Dieffenbacher is a globally leading manufacturer of hot press systems and complete production systems for wood-based panels. Its core equipment, the Continuous Panel System (CPS), has gained worldwide recognition since its introduction and continues to evolve.

Luli Wood Industry utilizes the world's longest Dieffenbacher CPS+ continuous press. With an effective press length of 64.5 meters and a width of 8.5 feet, this press employs built-in hydraulic cylinders to achieve a thickness control accuracy of 0.05mm—setting a world-leading benchmark as the highest-capacity single-line continuous press.

The CPS+ continuous press features a redesigned hydraulic cylinder layout where the main cylinders exert pressure directly onto the press's heating plates. This enhances flexibility in transverse pressure control while robust heating plate designs and parallel gap systems minimize frame deformation. Crucially, the thickness-adjustment zone for the green board has been optimized to maintain minimal transverse thickness variation, significantly improving both surface and edge quality.

An upgraded parallel control system for the pressing plate gap ensures balanced frame design parameters—such as heating plate thickness, cylinder count, and distance between upper/lower frames. This keeps the gap between upper and lower heating plates nearly consistent regardless of cylinder pressurization status, enabling uniform frame pressure distribution. Consequently, forces between cylinders and heating plates act flawlessly on the advancing board, preventing material rebound effects that disrupt core-layer curing and thickness control—ultimately enhancing product dimensional accuracy, reducing material waste, and improving surface quality.

Innovatively, the CPS+ integrates a cooling section tailored to China’s rising demand for MDI formaldehyde-free products. By converting the last few heating zones into cooling sections within the continuous press line, it delivers key advantages: 1) Rapid surface cooling reduces glue pre-curing and minimizes sanding allowances; 2) Higher permissible moisture content in the board accelerates core-layer curing, boosting line speed and productivity; 3) Lower post-press board temperature prevents water vapor condensation and bubble formation by easing internal steam pressure.